Stracture of Kimono

Have you ever wondered how kimonos are made?

When you make clothes, you buy fabric (such as 110cm width fabric in general) at a fabric store, cut it using a pattern, and use a sewing machine to make clothes.

Everything is different in the kimono. After the kimono fabric is made (see the Story of kimono fabric for the kimono fabric itself), it is handed over to a kimono tailor who specializes in tailoring kimonos.

In a typical clothing store, finished clothes are on hangers, but in a kimono shop selling Japanese kimonos, rolls of fabric are lined up on the shelves.

After selecting the fabric, the wearer's measurements are taken, and the selected fabric is made to order to fit those measurements.

Kimono fabric is finished in a roll approximately 12.5m long, 38 cm wide for women and 42 cm wide for men. This is read as a kimono fabric.

Each part is cut according to pre-measured measurements, and everything is sewn by hand.

Unlike clothing, there is no paper pattern and the garment is not cut in three dimensions, so there are no tucks.

The finished garment will be flat and wrinkle-free.

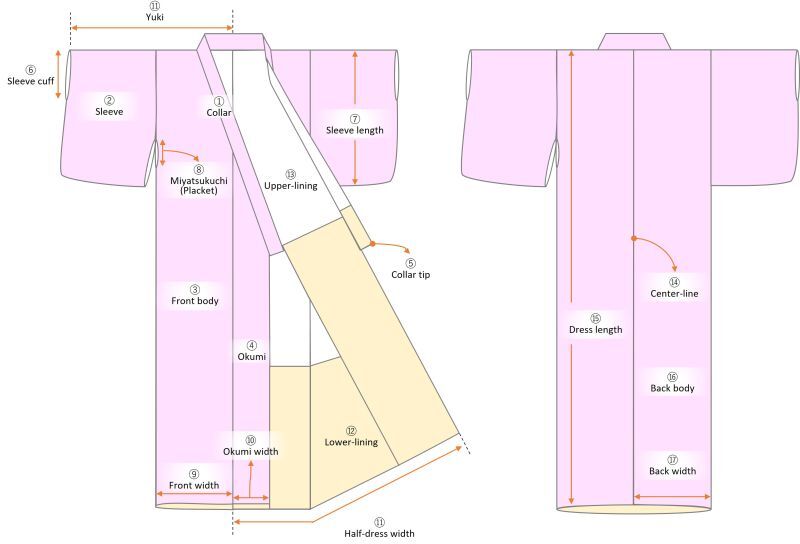

Each part of the kimono is as follows.

All of the above parts are cut from a single piece of fabric.

In this way, it may be a little easier to get a sense of kimono size.

Since the width of the fabric is fixed, a kimono of a certain width cannot be made in the first place.

However, within this range, it can be made to fit any size.

If there is excess fabric, do not cut it off and leave it between the lining and the fabric.

This has two advantages. One is that once the kimono is untied, it can be washed back into one piece of fabric.

This is called "Araibari" and allows the entire kimono to be washed without worrying about damage to the seams.

The other is that once untied, it can be remade into another size or another item, such as a haori or obi.

There is no limit to the number of items that can be tailored for your siblings or children, or made into a haori or obi by cutting off the damage part.

It is eventually re-cycled and used for baby diapers and even for dust cloth.

When you make clothes, you buy fabric (such as 110cm width fabric in general) at a fabric store, cut it using a pattern, and use a sewing machine to make clothes.

Everything is different in the kimono. After the kimono fabric is made (see the Story of kimono fabric for the kimono fabric itself), it is handed over to a kimono tailor who specializes in tailoring kimonos.

In a typical clothing store, finished clothes are on hangers, but in a kimono shop selling Japanese kimonos, rolls of fabric are lined up on the shelves.

After selecting the fabric, the wearer's measurements are taken, and the selected fabric is made to order to fit those measurements.

Kimono fabric is finished in a roll approximately 12.5m long, 38 cm wide for women and 42 cm wide for men. This is read as a kimono fabric.

Unlike clothing, there is no paper pattern and the garment is not cut in three dimensions, so there are no tucks. The finished garment will be flat and wrinkle-free.

Since the width of the fabric is fixed, a kimono of a certain width cannot be made in the first place.

However, within this range, it can be made to fit any size.

If there is excess fabric, do not cut it off and leave it between the lining and the fabric.

This has two advantages. One is that once the kimono is untied, it can be washed back into one piece of fabric.

This is called "Araibari" and allows the entire kimono to be washed without worrying about damage to the seams.

The other is that once untied, it can be remade into another size or another item, such as a haori or obi.

There is no limit to the number of items that can be tailored for your siblings or children, or made into a haori or obi by cutting off the damage part.

It is eventually re-cycled and used for baby diapers and even for dust cloth.